- Advantages & Uses

- Installation Instructions

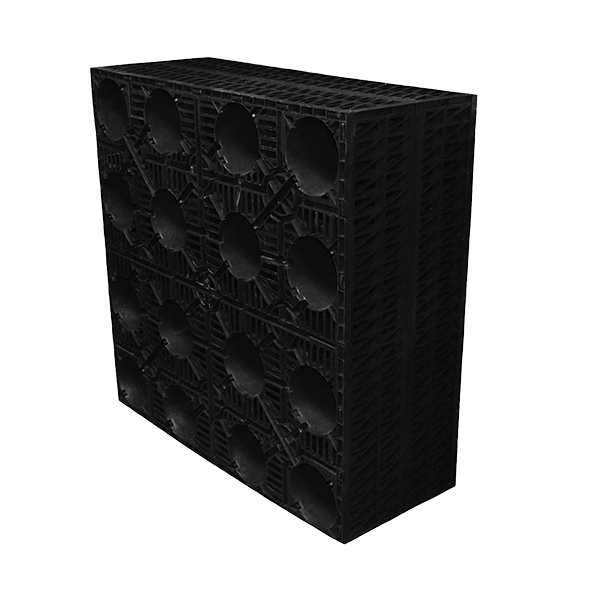

- Assembled ready to install with up to 72m³ on a full load

- Available in different configurations to meet specific load requirements

- 20 Tonne load bearing capacity

- Simple & fast to install with 2.5 units per m³

- Modular size of 1m x 1m plan x 400mm height ensures great versatility in both size and shape of storage

- Lightweight units under 25kg removes need for mechanical handling

- For permeable infiltration schemes, Soakaway units should be wrapped in our Stratacheck non-woven needle punched geotextile which allows water discharge through the subsurface whilst preventing the ingress of soil or sand particles

- For water storage, impermeable geomembrane is used between the geotextile & the crate assembly

- Prevents extreme peak flows to main drainage and water purification systems

- Rainwater is “cleaned” by geotextile surround

- Decreases possibility of flooding during heavy rain falls

Pre-installation notes: For attenuation systems: position the inflow and outflow connections level with the base of the structure

For infiltration systems: position the inflow connection at the top of the structure.

Installation Instructions:

1. Excavate to the required length, width and depth and level the base. Make sure that the area is enough to allow plant access around sides to compact the backfill material (500mm minimum for pedestrian only, 650mm for cars and 750mm minimum if HGVs being used over the tank).

Ensure the base is smooth and level with no sharp protrusions. Check that the slopes are cut back to a safe angle or adequately supported and that a safe access is possible to allow site personnel to enter the excavation.

2. Inspect the base for soft spots and if any are present, excavate and replace with compacted granular fill material.

3. Lay 75mm sharp sand bedding layer to the base of the excavation and level off. Lay the geotextile protection fleece (180g non woven, needle punched type GT1900), ensuring a minimum 150mm overlap. This is required for both attenuation and infiltration structures.

4. Lay the geomembrane (if tank is for water storage) over the geotextile and sand bedding layer and up the sides of the excavation. Examine the geomembrane for damage and test all welds if apparent.

5. Assemble the Crate units (1m x 1m x 0.4m High) and install within the void in accordance with the installation schedule for correct positioning. Special clips are provided to join the units to prevent displacement (single clips for adjacent units (3 per unit) and double clips for all multi layer applications (1per unit)).

6. Complete the geotextile and/or geomembrane encapsulation to the sides and top of the installation, ensuring that the protection fleece (if attenuation) has sufficient to overlap by 150mm minimum. The geomembrane should be welded with double seams and inspected for damage, testing the welds as required.

7. Connect the drainage connections to the installation using proprietary adaptors. Alternatively for infiltration systems use flange adaptors and attach them to the crate rate units with self tapping screws. For attenuated systems, it is recommended that all connections and air vent installations are achieved using sealed drainage connections into a preformed socket using proprietary seals “top hats” available to order.

8. Backfill around the installation with Type 1 or 2 sub base, compacting in 150mm layers, in accordance with the Specification for Highway Works.

9. Place a 75mm sharp sand protection layer if required over the top of units and continue to backfill as follows: For trafficked areas (car parks etc): Type 1 or 2 sub base material compacted in 150mm layers in accordance with the Specification for Highway Works. Compaction equipment on top of the system not to exceed 2,300kg per sq.metre. For landscaped and non-trafficked areas: Selected “as dug” material with a unit size no more than 75mm compacted to 90% maximum dry density. Compaction equipment on top of the system not to exceed 2,300kg per sq.metre.

10. Finalise the pavement construction / landscaping over the crate system.